Originally posted Sep 26, 2015

I decided to build a warp-weighted loom a couple years ago. I consulted a BUNCH of web sites (and Pinterest) and looked for sources (books) that I could look to, but most of the books I could find on warp-weighted looms is dated from before 1980.

Barber, Elizabeth Wayland. Women’s Work: The First 20,000 Years. W. W. Norton & Company; 1995.

Broudy, Eric. The Book of Looms. Brown University Press, 1979.

Broholm, H.C. and Hald, Margarethe. Costume in the Bronze Age in Denmark. Arnold Busck, 1940.

Hoffman, Marta. The Warp Weighted Loom. Robin and Russ Handweavers, 1974.

Trychkare, Tre. The Viking. Carver and Co., 1966.

Yeah. I looked for the Hoffman book, just out of curiosity, but the cheapest I can find is a used copy for $133 ($195 for a hard copy). Not happening on my budget. I’ll have to see if I can get a copy on inter-library loan. There appear to be a couple of newer magazine articles, so I’ll seek those out as well.

There are a lot of web sites with some research (most based on the sources above) plus looking at extant pieces and experimenting with building their own. There are differences with all of them, so other than the basic structure, there is a lot of room for experimentation and setting things up so it’ll work for the weaver. I still need to do a little more research on weaving in general–I’ve only done inkle and card weaving, but this seems to be just like a giant inkle loom. There are possibilities for doing multiple sheds, although the first couple of projects will be 2-shed only.

The other thing to keep in mind with this is that it is meant to be taken apart for transport to events. None of the joints are glued or permanently attached.

Identifying the parts of the loom are the first step to being able to build it.

- Upright

- Crotches

- Top stabilizing rod

- Warp beam

- Tensioner

- Warp threads

- Heddle rod

- More heddle rods

- Heddle Rod Support

- There are two things that are numbered 10…one is what looks like another heddle rod, the other is the finished weaving wrapped around the warp beam.

- Can’t find a number 11.

- Can’t find a number 12 either

- Warp weights

- Bundles of warps

- Chain stitched string to separate warp threads

(skipping 16-21)

22. Sword for beating

This was my process to building the prototype:

Take two 2 x 4s–I would recommend using two hard wood boards for a “finished” look, although Hemlock or Douglas Fir is certainly more economical and lighter for transport…I grabbed two boards from the rafters, only to realize later that the darker board was, in fact, cedar. Low light in the garage…Whoops!

I was looking at several sets of directions in the process. The first set said that I should cut two 2 x 4s to 7 feet long (84″). Other directions said keep the 2 x 4s at 8 feet long and use a stool to reach when weaving (which I would likely need for the 7′ tall uprights as well). To that I said, “What?! Oh, heck no!” I’m clumsy enough that I would likely fall off a stool, and being only 5 feet tall, I’d need a rather TALL stool for something 8 feet tall. Or maybe some stilts. I don’t need to risk injury on a super-size loom designed for a tall man. At the time, I left it at the 7′ measurement, but later on, as I will explain in a minute, I decided that I really didn’t need to make it much taller than me.

Next, you take those 24″ pieces that you cut off and make the “crotches”, seen in the above image. These are the pieces that the top beam rests in while you weave. It needs to be deep and wide enough for the rod to rest in, and taper down on the end so it can be screwed into the wood. Some directions suggest that you make it vaguely “S” shaped. Vague, indeed. Seems mostly stylistic, although the thinner end at the bottom makes it easier to attach to the boards with long screws. These were shaped using the band saw…I love that toy! The bottom of the crotch is 16″ down from the top of the upright leaving room for the top stabilizing rod.

.

The next step was creating the shed rod, which is the cross bar that sits about knee height made from a 1″ x 3″ board. This rod separates the front and back warp yarns; the back yarns go over the front, and the front yarns go over the back. It’ll all make sense later…. The top beam I bought is 5′ long, which determined the minimum width of the frame, but it also needed some overhang. 4″ on each side seemed adequate, so I cut the shed rod 52″. I drilled one hole through and secured it with a bolt and wing nut. I attached it right in the middle, then realized that it created a pivot point. I added a second bolt at the top, but they’re still a little close. I should put another one near the bottom and leave the center hole empty…next time, don’t drill the middle hole.

As I mentioned earlier, I attached a top stabilizing rod above the crotches. Some of the looms I’ve seen don’t have them, but it also appeared that the warp beams were very robust, but narrower where it fitted into the crotches, creating its own stability. For this project, however, I thought it was necessary to anchor it. This was also cut to 52″ and bolted in…just one bolt at each end, attached with wing nuts for easy assembly. Initially, I had the wing nuts to the back, like in this image, but the bolts were very long and scratching the walls, so I turned them around to the front.

The heddle rod supports were shaped from scraps in the bin, I think cut from leftover 1″ x 3″ pieces. They are about 8-10″ long and roughly Y shaped. I used the band saw again to shape this piece. I drilled a hole into the end and into the frame and used a piece of dowel to mount it onto the frame. These, likewise, can be easily removed for transport.

The heddle rod was the next piece. The plans I was following called for 7/8″ dowels, which I looked for at the hardware store, but they only had 4-foot lengths…I needed 5 feet. I realized that these don’t need to be particularly heavy or strong, and I just happened to have 3/4″ sticks that are more than long enough (leftover from the yurt project). More scavenging means more money savings for the prototype project!

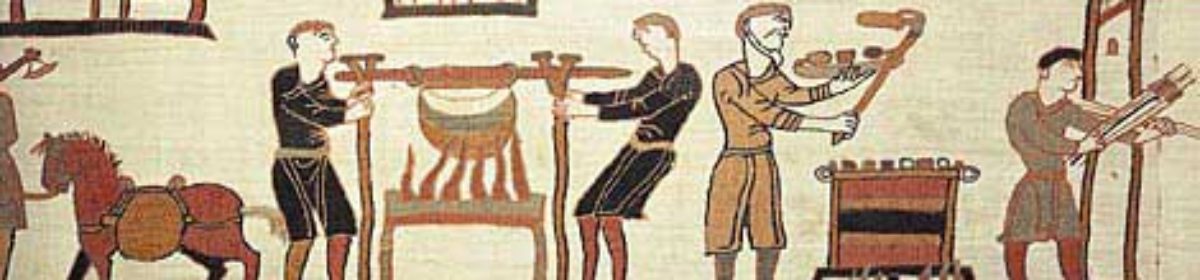

For the warp beam, where you attach the selvage band, I bought a piece of 2″ doweling. In some of the old-school looms I saw, like the one pictured above, the selvage band is sewn right onto a very large beam. In other images, it’s sewn into a bar that is somehow attached to the beam. I decided to attach a thin piece of wood into the dowel to sew the weaving onto.

Referring back to the Saami/Norwegian video of Mary Mikalsen Trollvik who was demonstrating how to set up the loom, she is weaving on a loom where the warp beam is at her head level. The more I thought about it, the more it made sense. Anything out of reach is just silly, so it was at this point that I decided that the top beam needed to be sitting at about 62″ instead of a ridiculous 78″. I disassembled it and cut it to size. Now she feels right.

Here she is, standing up! Maybe it seems weird, but at this point, she was starting to feel alive! She even told me her name. Frigga, named after the Norse Goddess of weaving and wisdom. There were a few more steps to complete my girl, but it was wintertime and it was just a few degrees above freezing in the garage, so this project was put on hold until warmer days.

Fast forward several months…

The Saami weaver, Mary Mikalsen Trollvik, started with a woven band with weft threads that become the warp threads of a woven piece. I had a bunch of Fisherman’s wool that was given to me and this seemed like a great project to use that yarn. I wove the selvage band, just the same way as Ms. Trollvik, and tied it onto a thin piece of wood–about 1/4″ thick and almost as long as the width between the uprights. At first, I had just tied it onto the dowel, but eventually, I put a couple screws into it to keep it from sliding around.

Then I set it up in January 2015 at Ursulmas and worked on the set up for several hours over the weekend, in between making beads for passers-by. By the end of the weekend, it was still no where near ready to weave on.

One of the things I hadn’t figured out was weights for the warp-weighted part. Ms. Trollvik and other Saami weavers use oblong rocks to weigh down the warp. Coming up with easy to transport weights was a bit more time consuming (I was still working on them up until the day before the Arts Unframed event). I needed it to be the right weight, easy to take off of the loom during transport, and not too heavy overall. Extant weights ranged from 1/2 lb. to 5 lbs. In my research, other weavers said that they have used 1/2 lb to 1-pound bags of sand or gravel for weights instead of clay circles or rocks. Some even used water bottles. I decided to go with bags of gravel–easy to make, easy to add or subtract weight as needed, and cheap.

I started making muslin bags with 5″ x 12″ pieces of fabric, folded long ways to make 2 1/2″ x 12″ tubes with an opening in the middle. I filled them with 1/2 lb. of pea gravel, evenly distributed into both ends, and hung it over the knotted lengths of yarn. I was planning on leaving it open, but decided rather than end up having gravel spilling everywhere during transport, I sewed them closed. I can always open it up and adjust as necessary.

Heddles were made from Maysville cotton warp. I thought this would be ideal since it would be less likely to get caught up in the wool fibers. The warp yarns are from “natural” color wool yarn that a friend was giving away. She got it from somewhere else and is allergic to wool and thought I’d get some use out of it. Why, yes I can!!

So finally, at the end of September, nearly a year after starting this project, I took the loom to the Arts Unframed event in the Barony of Wyewood. It took 3/4 of the day, but I got it up and running! I had to chain stitch the strings (two chains, front and back), bundle the warp to make half as many bundles, and then put the heddles back on.

Here it is all set up and ready to weave! You’ll now see that the back warps come forward through the heddles, then back behind the shed rod. The front warps lay down on the front of the shed rod. As you pull the heddle rod forward, the back warps come forward; you throw the weft, beat it into place, then put the heddle rod back. The back warps will hang behind and you can throw the weft again and beat.

While I didn’t get a lot done on the weaving (only about 2″), it broke down easily into three long pieces and a box of rocks (weights). It took about 10 minutes to take it apart and wrap it up in a sheet. It looks like a mummy, which makes sense since it was secured in this fashion by an Egyptologist.

When I got it home, it set up again in less than 10 minutes. I LOVE IT! This makes it easily transportable and I look forward to taking it to events like Ursulmas or even an outdoor event in the summer (weather permitting).

You note that the warp is darker than the weft…I ran out of the natural yarn and had to switch to the white yarn. I don’t know how many skeins I’ll need, and since Fred Meyer doesn’t appear to carry the yarn anymore, I may have to source more online, if need be. The blue yarn, just so you know, is the same Fisherman’s yarn that I dunked into a Kool Aid dye. Yep. Kool Aid!

My plan is to (very soon) obtain some wood in a more natural and rustic state to make a loom that looks a little more like this:

I hope you enjoyed reading about my venture into building a warp weighted loom! If you are inspired to build your own, please send me a picture of your finished product!

![More of the odd "midwife" apron from a Saxon lineage book. Das Sächsische Stammbuch' [subtitled as:] 'Sammlung von Bildnissen sächsischer Fürsten, mit gereimtem Text; aus der Zeit von 1500 - 1546' is available online from the State University Library in Dresden: More of the odd "midwife" apron from a Saxon lineage book. Das Sächsische Stammbuch' [subtitled as:] 'Sammlung von Bildnissen sächsischer Fürsten, mit gereimtem Text; aus der Zeit von 1500 - 1546' is available online from the State University Library in Dresden](https://s-media-cache-ak0.pinimg.com/736x/cb/1c/f9/cb1cf9187f5e0b10281191faf494139b.jpg)

![Isabella of Hainault (Valenciennes,[1] 5 April 1170 – 15 March 1190, Paris) was queen consort of France as the first wife of King Philip II of France.](https://s-media-cache-ak0.pinimg.com/736x/cd/4e/ee/cd4eee040eba4ee754652b5adf164094.jpg)

Measure from the corner of the buckram to a few points on the line to get an average measurement. Use this radial measurement to get an even circle-segment drawn on the buckram.

Measure from the corner of the buckram to a few points on the line to get an average measurement. Use this radial measurement to get an even circle-segment drawn on the buckram. Cut the buckram and join together at the short edge to make the fillet.

Cut the buckram and join together at the short edge to make the fillet. Pin the pleats onto the middle of the fillet’s band, all the way around. Carefully fold the pleated fabric over the top and bottom. The pleats may expand or contract because of the angle of the fillet. Pin securely, then baste the covering together on the inside of the fillet.

Pin the pleats onto the middle of the fillet’s band, all the way around. Carefully fold the pleated fabric over the top and bottom. The pleats may expand or contract because of the angle of the fillet. Pin securely, then baste the covering together on the inside of the fillet.